Rotary Tables

Precise Rotational Handling, Integrable into Your Automated Systems

Meccanica Besnatese rotary tables are designed to optimize the movement and positioning of components within automatic and semi-automatic machines.

Used as a rotating platform to compensate positions, rotate parts, or assist the operator, they ensure smoothness, precision, and repeatability, even in the most demanding cycles.

Available in various sizes and configurations, they integrate easily with standard linear tables, especially in projects requiring multi-axis motion.

RT and RTC Series Rotary Tables

Rotational Precision for Industrial Applications

The RT and RTC rotary tables are designed to perfectly integrate into automatic and semi-automatic handling systems.

Both series feature a compact, robust, and customizable structure and offer reliable performance for various industrial applications, particularly for semi-machines and custom systems.

Advantages:

- Smooth and repeatable motion

- Precise rotation even under load

- Modular structure compatible with BB or UMB linear tables

- Optimized dimensions and customizable mechanical options

- In-house production with full control over every phase, from table body to accessories

- Higher load capacity compared to competitors

- Ideal for integration into semi-machines and automated systems

Applications:

Industrial automation

Special machines

Food and packaging sectors

Industrial transfer systems

Automotive

Medical

Pharmaceutical

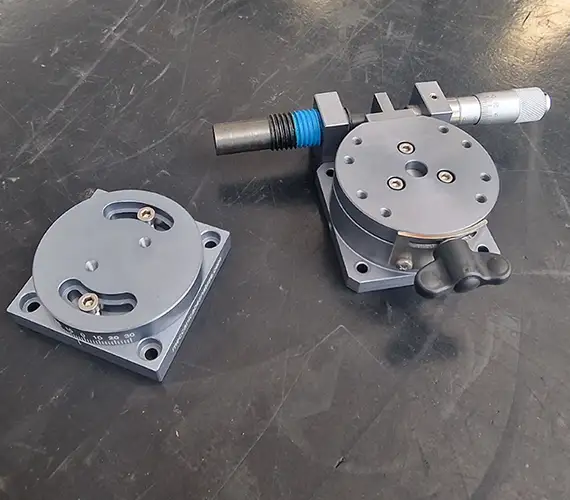

TRP ACCESSORIES

The swivel base allows rotation of +/- 15° around its axis. Rotation is adjusted using a micrometric head and a contrast pin.

The swivel base can be combined with all single and double axis models of the TRP60 table, and can be mounted either above or below them.

Applications

Pharmaceutical

Medical

Food and packaging sectors

Research laboratories

Why Choose Meccanica Besnatese Rotary Tables?

Smooth and precise motion thanks to ground ball screws

High load capacity, even for demanding applications

Guaranteed repeatability for high-frequency production cycles

In-house design and manufacturing: every table is machined in our workshops

Complete customization for dimensions, stroke, and interfaces

Reduced operational costs through process automation

Superior reliability compared to competitors who assemble third-party components

Machine Park for Rotary Table Production

Each rotary table is made in-house with CNC machining centers, grinders, and the new 5-axis milling machine, allowing 24/7 machining of large table bodies with micrometric precision, even for critical applications such as aerospace.

Custom Linear Tables

for Every Industry

Meccanica Besnatese is the ideal partner for integrators, designers, and companies in the following sectors:

Industrial automation

Hydraulics

Pharmaceutical

Food

Aerospace

Automotive

Energy and Oil & Gas

Medical and research

Looking for a Handling Solution or Specific Machining?

Ask the technical experts at MECCANICA BESNATESE

You’ll receive a quick response and direct consultation for the development of your project.