Linear Technology

Handling Solutions for Every Industrial Need

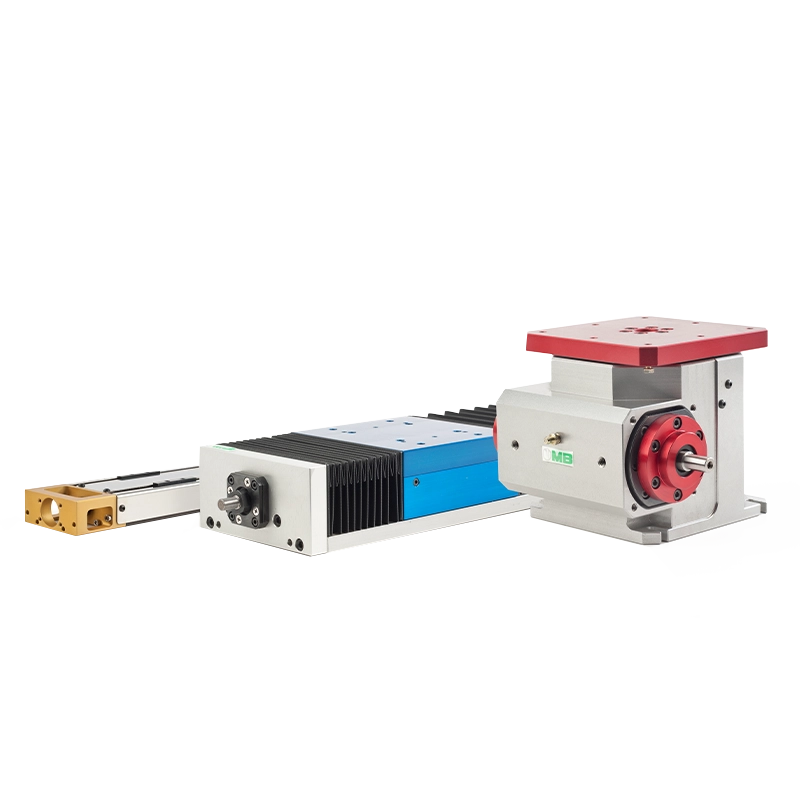

Meccanica Besnatese Linear Tables

From manual handling to automatic handling, to the creation of special and fully customized tables: with Meccanica Besnatese, you have a technical partner with over 65 years of experience, a complete in-house machine park, CNC mechanical expertise, and a team capable of supporting you from design to commissioning.

We design and manufacture linear slides, sliding guides, linear axes, and positioning tables for every type of application. Our solutions are used in industrial automation, laboratories, assembly lines, special machines, and harsh environments.

All our tables are internally manufactured to guarantee precision, rigidity, customization, and superior quality compared to competitors.

Linear Tables

Reliable Handling, from Manual Positioning to Automated Control

We design and manufacture standard linear tables for manual positioning or automated movement control.

Manual versions are ideal for occasional adjustments and controlled environments (medical, food, pharmaceutical), while motorized versions ensure speed, repeatability, and precision in automation systems.

All tables are internally manufactured with robust structures, stainless steel guides, and precision-ground ball screws, ensuring superior performance and long lifespan.

Reliable Handling

Custom Tables

Special and Custom Tables

Tailor-Made Systems for Non-Standard Handling

Meccanica Besnatese special tables are designed based on the actual needs of the customer: dimensions, materials, stroke, configuration, and accessories are customized through a structured process that includes requirement gathering, project design, validation, manufacturing, and testing.

We also produce rotary tables, presetting tools, and roller guide tables for heavy-duty applications. Workable dimensions reach up to 3,000 x 6,000 mm, with loads up to 10,000 kg.

Rotary Tables

Precise Rotation Integrated into Any Automated System

Meccanica Besnatese rotary tables are designed to rotate components or equipment in a controlled, smooth, and repeatable manner. The RT and RTC series integrate perfectly with our linear tables and are used in automated machines, robotic stations, production lines, and medical environments.

Rotary Tables

Why Choose Meccanica Besnatese for Your

Linear Technologies

A technical partner for the design and manufacture of customized handling systems.

Technical consulting on design, application, or specific requirements.

In-house design and production of every component for full control.

Standard, special, and custom tables made to measure with optimized materials and geometries.

Precision, rigidity, and smooth movement guaranteed, even with heavy loads or harsh applications.

Testing and prototyping department to validate every table before delivery.

Fast response and direct technical support, even post-installation.

Machine Park for the Production of Linear Tables

Each table is made in-house with CNC machining centers, grinders, and the new 5-axis milling machine, enabling 24/7 machining of large table bodies with micrometric precision, even for critical applications like aerospace.

Looking for a Handling Solution or Specific Machining?

Ask the technical experts at MECCANICA BESNATESE

You’ll receive a quick response and direct consultation for the development of your project.